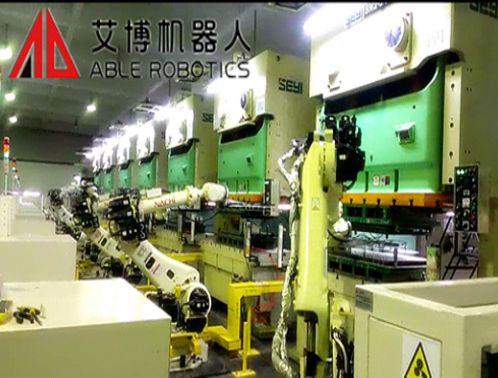

The customer product is engine crank, the front material is disorderly, the nc machine tool processing to the product placement accuracy high requirements. Realize the standard automatic feeding and unloading of mixed materials.

The 3D camera (taking the curved surface) takes pictures and sends the data to the robot. The robot adjusts the Angle to grab the product and puts it on the center turntable. Then, the 2D camera (taking the plane) takes pictures for precise positioning. The robot adjusts the Angle again and puts the product into the machine tool fixture. Through the double combination of a 3D camera and two 2D cameras, high precision feeding and feeding can be realized.

Features: high precision, fast beat, the use of industry-leading visual guidance technology, no requirements on customer incoming materials, greatly saving the customer's manpower and material resources, convenient production and operation.

|

|

|

| 3C industry | Machine industry | Injection molding industry |

|

|

|

| Medical instruments | Food Industry | Auto parts industry |